Scroll to:

Experimental studies of the influence of the characteristics of the metal bond coat on the durability of the heat-protective coating of the turbine blades of a gas turbine engine

https://doi.org/10.26467/2079-0619-2025-28-5-41-49

Abstract

The service life of gas turbine engine (GTE) turbine blades with thermal barrier coatings (TBC) depends on many factors, including the composition, structure and properties of the metal bond coating (MB). The positive effect of using TBC is well known: an increase in the service life of the protected part or an increase in the working gas temperature in front of the engine turbine. At the same time, it is also obvious that the development and implementation of new TBCs that use more efficient TBCs is an urgent task. The efficiency and service life of TBCs are significantly affected by the following characteristics of the metal bond coat: material, its thickness and microstructure, and application method. In order to select a rational metal bond coat of the TBC and to assess its performance on turbine blades at high temperatures, a comparative analysis of the isothermal heat resistance of TBCs with different versions of metal bond coats and at different operating temperatures was performed. The time , up to which the total area of ceramic layer chips on the leading edge and trough does not exceed 30%, was adopted as the isothermal heat resistance criterion. Tests of GTE process blades made of ZhS32VI alloy with TBCs with various metal bond coats applied to them using serial technology were carried out at temperatures of 1100 °C and 1170 °C. The isothermal heat resistance test base was at least 500 hours. Four process blades with each of the studied coating options were tested. Analysis of the obtained test results showed that TBCs with a NiCrTaY and AZh-8+CrAl sublayer have higher durability indicators. This effect is due to the presence of refractory elements (tantalum and yttrium) in the MB, which create a diffusion barrier and slow down the growth of the Al2O3 oxide film formed on the metal layer. During the experimental studies it was established that the composition of the metal bond coat in the TBC design significantly affects its durability. Thus, the absolute values of can differ several times. With an increase in the temperature of isothermal tests, a significant (2–3 times) decrease in the durability of the coating is observed. Therefore, the correct choice of the MB composition allows you to reduce the level of stress-strain state at the boundary of the layers, increase the adhesion strength, and thereby increase the durability of the TBC.

Keywords

For citations:

Samoilenko E.V., Ugreninov V.G., Shestakov V.V. Experimental studies of the influence of the characteristics of the metal bond coat on the durability of the heat-protective coating of the turbine blades of a gas turbine engine. Civil Aviation High Technologies. 2025;28(5):41-49. https://doi.org/10.26467/2079-0619-2025-28-5-41-49

Introduction

The durability of gas turbine engine (GTE) turbine blades with thermal barrier coatings (TBCs), operating at high temperatures, depends on many factors, including the composition, structure, and properties of the metal bond coat. The determining characteristics of the bond coat are its composition and the application method [1–6]. The positive effect of using TBCs is well-established: it increases the service life of the protected component or allows for a higher temperature of the gas entering the turbine. At the same time, it is evident that the development and implementation of new, more effective TBCs, more efficient bond coats, and improved methods for their application is a relevant and important task. A typical structure of a TBC is shown in Figure 1.

Fig. 1. Typical structure of the TBC of a gas turbine engine blade

(top to bottom: heat flux, ceramic thermal barrier coating, metal bond coat, blade material)

Generally, the required temperature of the blade base material for long-term operation is achieved by improving the blade’s design, reducing the heat flux intensity, and selecting the composition and thickness of the TBC.

Let us assume that the heat flux intensity and the blade design are given. In this case, the efficiency of the thermal barrier coating is enhanced by selecting its optimal thickness and the specific thermal conductivity value of the ceramic layer. It is important to consider that under long-term cyclic loading (both thermal and mechanical), degradation of the TBC occurs. This manifests itself in oxidative processes at the interface between the ceramic layer and the bond coat, changes in the microstructure of the ceramic layer itself (recrystallization, sintering), and effects of hot corrosion and erosion of the ceramic layer. In particular, the sintering of the ceramic layer after cyclic thermal exposure (fig. 2) leads to the formation of defects such as pores, cracks, and vertical channels of the columnar structure, which causes an increase in the thermal conductivity of the ceramic layer [1][7–9].

Fig. 2. Appearance of the ceramic layer ZrO2+8%Y2O3 at the sintering site and when cracks appear

The process of TBC destruction begins from the moment a portion of the ceramic layer spalls off the surface of the cooled blade, after which it stops performing its main function – protecting the blade metal from high temperatures. However, cracks in the ceramic layer of the TBC and the formation of fragments of various sizes are a reaction to operational stresses and surface deformations of the blades, which does not yet indicate a loss of the TBC’s protective functions.

It is known [10–14] that one of the critical areas of a TBC, directly affecting its durability, is the interface between the ceramic layer and the heat-resistant bond coat. During the operation of blades with TBCs, oxygen gets through the ceramic layer to the bond coat, leading to its oxidation and the growth of an aluminum oxide (Al2O3) layer (fig. 3).

Fig. 3. Typical microstructure of the TBC at the boundary of the ceramic layer and the metal bond coat after operation

(top to bottom: heat flux, Al2O3, ceramic thermal barrier coating)

There are two primary pathways for oxygen delivery to the interface known: gas transport through the open porosity of the ceramic layer and the diffusive movement of oxygen ions through anion vacancies in the zirconia dioxide lattice. Oxides form on the surface of the bond coat; their composition and structure depend on the amount of oxygen supplied and the composition of the bond coat itself. This creates additional internal stresses at the bond coat interface, reduces the adhesion of the ceramic layer, and leads to its spallation. These processes are one of the main reasons for TBC failure [2][14].

The efficiency and durability of a TBC largely depend on the characteristics of the metal bond coat (material, its thickness and microstructure, application method). To select an optimal metal bond coat for the TBC and to assess its serviceability on turbine blades under high temperatures, this work presents a comparative analysis of the isothermal heat resistance of TBCs with various bond coat options at different operating temperatures.

Research methods

Tests were conducted on the GTE blades made of ZhS32VI alloy, coated with TBCs applied via the standard production technolo-gy [8–10][15] but with different metallic bond coats. The tests were carried out at temperatures of 1100°C and 1170°C. The baseline for the isothermal heat resistance tests was at least 500 hours. Four blades were tested for each variant of the coating. The tests were performed in an ET-2 type furnace. During the testing, samples were selected for analysis after 5, 20, 50, and subsequently every 100 hours.

During the isothermal exposure, the failure of the TBC is practically independent of thermal shock stresses (which only occur during loading and unloading of the samples for inspection and weighing). Consequently, it can be stated that in this study, the determining role in the failure of the ceramic layer is played by the oxidation process of the bond coat, and changes in its composition and structure due to diffusion processes.

The time until the total area of ceramic layer spallation on the leading edge and the pressure side does not exceed 30% was adopted as the criterion for isothermal heat resistance. Particular attention was paid to the condition of the heat-resistant bond coat in the areas of the spalled ceramic.

Research results

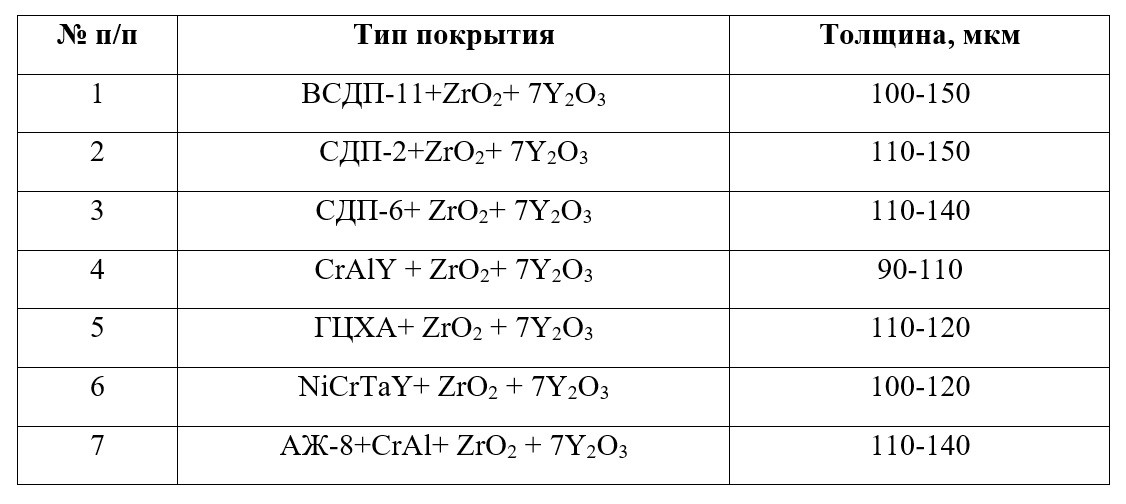

Various bond coat options were applied using the standard production technology. Subsequently, a ceramic layer of ZrO2·7%Y2O3 was deposited on all blades via electron-beam evaporation and condensation in a vacuum. The investigated coating variants and their thicknesses are presented in Table 1. The test results are shown in Figure 4 and Figure. 5.

Table 1

Variants of the investigated coatings

(left to right: type of coating, thickness in microns)

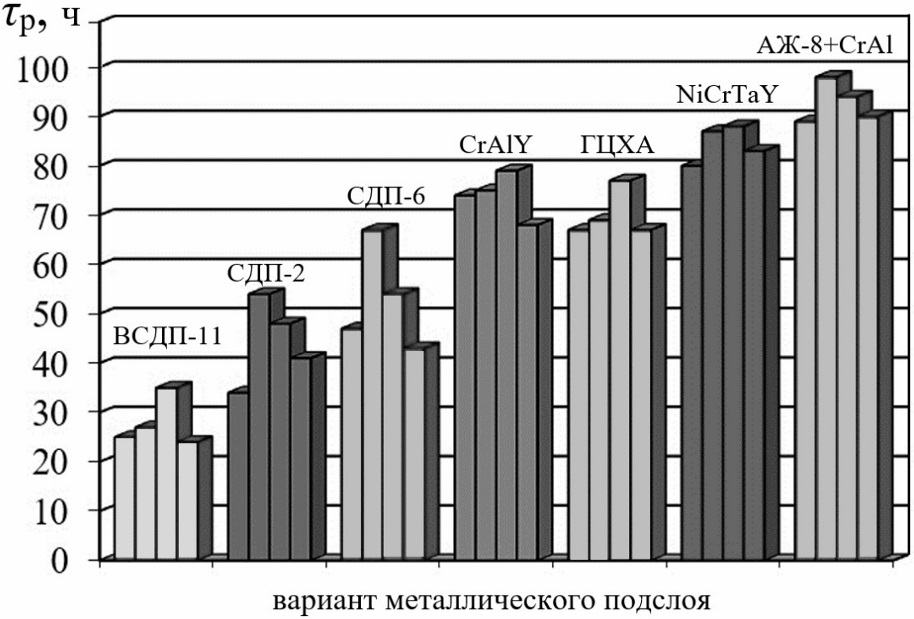

Fig. 4. Diagram of coating tests for isothermal heat resistance at a temperature of 1100 °С

with variants of metal bond coatings

(top to bottom: time, hours; variant of metal coating)

Fig. 5. Diagram of testing coatings for isothermal heat resistance at a temperature of 1170 °C with variants of metal bond coatings

Analysis of the obtained test results showed that the TBCs with the NiCrTaY and

AZh-8+CrAl bond coats exhibited higher durability. This effect is due to the presence of refractory elements (tantalum and yttrium) in the bond coat, which create a diffusion barrier and slow down the growth of the Al2O3 oxide film forming on the metal layer. Consequently, the initial state of the coating is maintained for a longer period.

It is evident that the integral durability indicator of the multilayer coating significantly depends on the choice of the bond coat. As can be seen from Figure 4 and Figure 5, the absolute values of can differ by several times. With an increase in the temperature of the isothermal tests, a significant (2 to 3 times) reduction in coating durability is observed. This can be explained by the increased intensity of diffusion processes occurring between the TBC and the base alloy, as well as the accelerated development of oxidative processes.

At the higher temperature (1170 °C), processes of cubic and tetragonal phase decomposition occur in the TBC’s ceramic layer, with the possible appearance of a monoclinic phase. This ultimately leads to an increase in compressive stresses within the ceramic layer, followed by its spallation from the bond coat.

Cоnclusion

It has been established through experimental research that the composition of the metallic bond coat in a TBC structure significantly influences its durability, . The absolute values of can vary by several times. A significant (2 to 3 times) decrease in coating durability is observed with an increase in the temperature of the isothermal tests. Therefore, the correct choice of the bond coat composition helps to reduce the stress-strain state level at the interface between the layers, increase the adhesion strength, and thereby enhance the TBC's durability.

Based on the conducted research, to increase the durability of the entire TBC system, it is advisable to use the AZh-8+CrAl metallic bond coat. Its chemical composition is similar to that of the nickel-based alloys used for manufacturing blades in modern gas turbine engines. This helps to reduce diffusion processes between the bond coat and the base alloy. Furthermore, the presence of refractory elements (tantalum and yttrium) in the bond coat somewhat slows down the growth of the oxide film, which also positively impacts the overall durability of the TBC.

References

1. Budinovskiy, S.A., Chubarov, D.A., Matveyev, P.V. (2014). Modern methods for deposition of thermal barrier coatings on GTE turbine blades. Aviatsionnyye materialy i tekhnologii, no. S5, pp. 38–44. (in Russian)

2. Abraimov, N.V., Eliseev, Yu.S. (2001). Chemical-thermal treatment of heat-resistant steels and alloys. Moscow: Intermet Inzhiniring, 620 p. (in Russian)

3. Abraimov, N.V., Abraimov, A.N., Terentyeva, V.S. (1996). Analysis of damageability of turbine blade coatings of aviation gas turbine engines in operation. In: Zashchitnyye pokrytiya: nauchno-metodicheskiye materialy. Moscow: VVIA im. N.Ye. Zhukovskogo, pp. 2–8. (in Russian)

4. Samoilenko, V.M., Fatyanov, E.A., Ravilov, R.G., Kazaryan, V.A. (2010). The influence of the nature of the metal sublayer on the durability of the thermal barrier coatings. Korroziya: metally, zashchita, no. 2, pp. 32–35. (in Russian)

5. Weng, W.-X., Wang, Y.-M., Liao, Y.-M., Li, C.-C., Li, Q. (2018). Comparison of microstructural evolution and oxidation behaviour of NiCoCrAlY and CoNiCrAlY as bond coats used for thermal barrier coatings. Surface & Coatings Technology, vol. 352, pp. 285–294. DOI: 10.1016/j.surfcoat.2018.08.024

6. Mednikov, A.F., Medvedev, K.S., Kachalin, G.V., Tkhabisimov, A.B., Kachalina, E.V. (2023). Modern methods of forming thermal barrier coatings: a review. Globalnaya Energiya, vol. 29, no. 4, pp. 132–148. DOI: 10.18721/JEST.29409 (in Russian)

7. Samoylenko, V.M., Aksenov, A.N., Ravilov, R.G., Opokin, V.G. (2023). Protective coatings for turbine blades of III-IV generation. Elektrometallurgiya, no. 1, pp. 21–28. DOI: 10.31044/1684-5781-2023-0-1-21-28 (in Russian)

8. Baldaev, L.Kh., Baldaev, S.L., Mazilin, I.V., Akhmetgareeva, A.M., Ivanov, A.S. (2016). Application of thermal barrier coatings for blades of modern gas turbine units using the example of GTD-110M. Safety and Reliability of Power Industry, no. 2 (33), pp. 70–72. (in Russian)

9. Loshchinin, Yu.V., Razmakhov, M.G., Pakhomkin, S.I., Lutsenko, A.N. (2019). Influence of structure and technology of drawing of multilayer heat-protective coatings produced by thermal spraying dusting on thermal conductivity. Proceedings of VIAM, no. 6 (78), pp. 95–103. DOI: 10.18577/2307-6046-2019-0-6-95-103 (in Russian)

10. Budinovsky, A.A., Muboyadzhan, S.A., Gayamov, A.M. (2008). Current state and main trends in the development of high-temperature thermal barrier coatings for working turbine blades of aviation gas turbine engines. Aviatsionnaya promyshlennost, no. 4, pp. 33–37. (in Russian)

11. Samoylenko, V.M., Paschenko, G.T., Samoylenko, E.V., Gnezdilova, A.A. (2023). Influence of impurities contained in fuel and air on sulfide corrosion of turbine blades of the gas turbine engine. Civil Aviation High Technologies, vol. 26, no. 1, pp. 72–80. DOI: 10.26467/2079-0619-2023-26-1-72-80

12. Sankar, V., Ramkumar, P.B., Sebastian, D., Joseph, D., Jose, J., Kurian, A. (2019). Optimized thermal barrier coating for gas turbine blades. Materialstoday: Proceedings, vol. 11, part 3, pp. 912–919. DOI: 10.1016/j.matpr.2018.12.018

13. Tolmachev, Ya.V., Zavarzin, S.V., Loshchinina, A.O., Knyazev, A.V. (2023). High temperature oxide corrosion of ceramic materials in turbine engines. Proceedings of VIAM, no. 7 (125), pp. 69–83. DOI: 10.18577/2307-6046-2023-0-7-69-83 (in Russian)

14. Petrov, Yu.V., Samoylenko, V.M., Ratenko, O.A., Samoylenko, E.V. (2024). Use of protective coating to renewal operability of turbine blades of gas turbine engine, taking into account their operational damages. Elektrometallurgiya, no. 9, pp. 12–23. DOI: 10.31044/1684-5781-2024-0-9-12-23 (in Russian)

15. Abraimov, N.V., Ovchinnikov, V.V. (2023). High-temperature materials, coatings and welding in aircraft and engines. Moscow: Nauka i tekhnologii, 636 p. (in Russian)

About the Authors

E. V. SamoilenkoRussian Federation

Elizaveta V. Samoilenko, Lecturer of the Chair of Technical Mechanics and Engineering Graphics

Moscow

V. G. Ugreninov

Russian Federation

Vladimir G. Ugreninov, Candidate of Technical Sciences, Associate Professor of the Chair of Technical Mechanics and Engineering Graphics

Moscow

V. V. Shestakov

Russian Federation

Vladimir V. Shestakov, Candidate of Technical Sciences, Lead Engineer

Lytkarino

Review

For citations:

Samoilenko E.V., Ugreninov V.G., Shestakov V.V. Experimental studies of the influence of the characteristics of the metal bond coat on the durability of the heat-protective coating of the turbine blades of a gas turbine engine. Civil Aviation High Technologies. 2025;28(5):41-49. https://doi.org/10.26467/2079-0619-2025-28-5-41-49